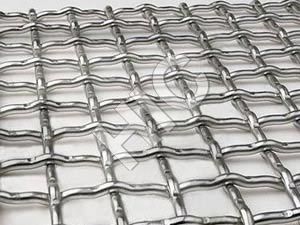

Crimped Woven Wire Mesh

Product Details:

- Surface Treatment Galvanized / PVC Coated / Uncoated

- Aperture 3 mm to 100 mm

- Length 1 m to 30 m

- Wire Gauge 2 mm to 12 mm

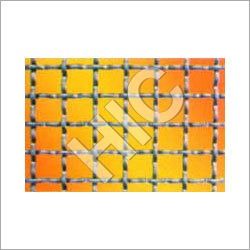

- Hole Shape Square / Rectangular

- Product Type Crimped Woven Wire Mesh

- Mesh Type Woven / Welded

- Click to View more

X

Crimped Woven Wire Mesh Product Specifications

- Crimped

- Custom sizes, typically 1 m x 2 m, 1.2 m x 2.4 m

- Square / Rectangular

- Silver / Black / Customized

- Stainless Steel, Mild Steel, Galvanized Iron

- 2 mm to 12 mm

- Sieving, Fencing, Mining, Construction, Quarrying, Decoration

- 2 mm to 12 mm

- Varies by size and wire diameter

- 1 m to 30 m

- 3 mm to 100 mm

- Woven / Welded

- 304 / 316 Stainless Steel, Mild Steel

- Galvanized / PVC Coated / Uncoated

- Crimped Woven Wire Mesh

Product Description

Supported by rich expertise of 47 years in this domain, we are engaged in manufacturing, exporting and supplying a wide assortment of Crimped Woven Wire Mesh. At our advanced production unit, the offered mesh is manufactured using supreme grade raw materials and innovative techniques under the supervision of deft professionals as per set industry norms. The provided mesh is used as vibrating screen in the mining, coal, crusher and other industries. Moreover, we offer this Crimped Woven Wire Mesh to our patrons at cost effective rates.

Features:

Features:

- Rust proof

- Longer life

- Sturdy design

- Fine finish

Exceptional Durability and Customization

Designed to withstand harsh environments, these meshes offer up to 10 years of service life. With precise thickness tolerance (0.05 mm) and customizable aperture, color, and dimensions, they fulfill a wide range of application needs. Customers can select from various surface treatments such as galvanized or PVC-coated finishes, further enhancing corrosion resistance and longevity.

Efficient Applications Across Industries

Crimped woven wire mesh serves diverse functions: from efficient sieving and security fencing to heavy-duty use in mining and construction. The robust weave structure and choice of edge treatments (cut or bent) contribute to stability and safety, making them suitable for demanding operational conditions. Available mesh shapes include square, rectangular, and custom options.

FAQs of Crimped Woven Wire Mesh:

Q: How is crimped woven wire mesh manufactured to ensure strength and durability?

A: This mesh is produced using high-quality materials like stainless steel, mild steel, or galvanized iron, and woven in Double Crimp, Intermediate Crimp, or Lock Crimp patterns. Advanced weaving processes provide consistent mesh apertures and robust construction, while precision edge treatments contribute to its stability and safety.Q: What sizes and customization options are available for the mesh?

A: Clients can choose opening sizes ranging from 3 mm to 100 mm and wire gauges between 2 mm and 12 mm. The mesh is available in standard panel sizes such as 1 m x 2 m and 1.2 m x 2.4 m, or in rolls up to 30 m in length. Custom dimensions, colors, and surface treatments can also be specified based on project requirements.Q: When should stainless steel or galvanized finishes be used?

A: Stainless steel mesh is recommended for applications requiring high corrosion resistance and temperature tolerance up to 800C, such as chemical processing or high-heat environments. Galvanized finishes provide substantial corrosion resistance at a lower cost, ideal for outdoor fencing or non-extreme industrial uses.Q: Where is crimped woven wire mesh best utilized?

A: This mesh is widely used in sectors like mining, quarrying, construction, sieving, fencing, and decorative installations. Its versatility also makes it suitable for architectural projects, filtration systems, animal enclosures, and safety barriers.Q: What is the typical usage life and what factors influence its longevity?

A: Depending on material choice and environmental conditions, the mesh generally lasts 5 to 10 years. Stainless steel options in less corrosive environments offer the longest lifespan, while proper surface treatments and maintenance extend durability even further.Q: How is the mesh delivered and what packaging options are provided?

A: Mesh can be supplied in rolls or flat panels, securely wrapped in plastic film and wooden cases for protection during transport. Customized packaging methods are available to meet large-scale industrial needs or specific shipping requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Crimped Wire Mesh' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |