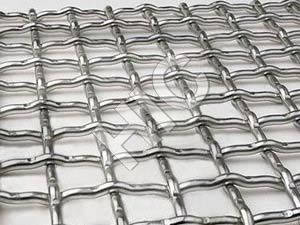

Crimped Mesh

Product Details:

- Surface Treatment Galvanized or Uncoated

- Wire Gauge 2 mm to 12 mm

- Length As required / Customizable

- Aperture 6 mm to 100 mm

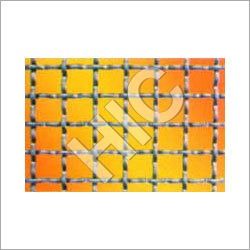

- Hole Shape Square

- Product Type Crimped Mesh

- Mesh Type Woven Wire Mesh

- Click to View more

Crimped Mesh Price And Quantity

- 1 Roll

Crimped Mesh Product Specifications

- Galvanized or Uncoated

- Crimped

- As required / Customizable

- 2 mm to 12 mm

- MS, SS 304, SS 316

- Woven Wire Mesh

- Silver Grey (metallic)

- 6 mm to 100 mm

- Square

- Mild Steel, Stainless Steel

- 2 mm to 12 mm

- Crimped Mesh

- Sheet or Roll, as per requirement

- As per specification / Custom

- Fencing, Sieving, Mining, Quarrying, Security, Construction

Crimped Mesh Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- 5 Roll Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

Crimped Mesh

Since inception in the year 1969, we have establish ourselves as a leading manufacturers, exporters and suppliers of optimum quality Crimped Wire Mesh. This wire mesh is precisely manufactured under the direction of our ingenious professionals by making use of superior quality brass, stainless steel, carbon steel and many more. The offered wire mesh has the stable structure and is perfect to be used in coal and mine, building etc. fields. Our provided Crimped Wire Mesh is available in various specifications as per the requirement laid down by our clients.

Features:

-

Withstand all extreme weather conditions

-

Durable finish standard

-

Strong in structure

-

Less maintenance

Engineered for Strength and Versatility

Our Crimped Mesh is designed to meet demanding industrial requirements. With wire diameters ranging from 2 mm to 12 mm and apertures between 6 mm to 100 mm, it accommodates a wide array of applications. This mesh is suitable for both fencing and filtration, making it an ideal choice for sectors such as mining, quarrying, security, and construction.

Superior Durability and Customization

Possessing high tensile strength and corrosion resilience, our mesh endures harsh environments. Clients can select from galvanized or stainless-steel options for enhanced protection against rust. Tailored roll widths up to 2 meters and configurable lengths ensure the mesh fits every unique project, while various edge finishes deliver easy installation and safety.

FAQs of Crimped Mesh:

Q: How is crimped mesh with edge finish used in industrial applications?

A: Crimped mesh with edge finishes such as welded or selvage is commonly used in fencing, sieving, mining, and construction. Its robust build allows it to endure heavy-duty tasks, act as safety barriers, filter materials, or provide structural support in both indoor and outdoor environments.Q: What are the benefits of choosing galvanized or stainless steel surface treatments?

A: Galvanized and stainless steel treatments significantly increase mesh life by providing high corrosion resistance, especially important for prolonged exposure outdoors or in factories. Stainless steel grades also offer superior temperature resistance up to 800C, ideal for demanding industrial conditions.Q: When should I opt for a custom bundle or roll packaging for my project?

A: Custom bundle or roll packaging is advantageous when you require mesh in specific lengths or need easy handling and storage. This flexibility helps streamline installation and minimizes waste, particularly in projects with unique dimensional requirements.Q: Where can crimped woven wire mesh be installed?

A: Crimped mesh can be installed in a variety of environments including construction sites, industrial plants, quarries, mining areas, and around residential or commercial properties for fencing and security purposes. It performs well both indoors and outdoors due to its resilience.Q: What factors should I consider when selecting mesh aperture and wire gauge?

A: Selecting the right aperture and wire gauge depends on your applications needs. Larger apertures and thicker wire suit heavy-duty sieving or security fences, while smaller apertures and lighter gauges are ideal for fine filtration and light enclosures. Customization is available to match specific project demands.Q: How is the crimped mesh manufactured and finished?

A: This mesh is woven from high-tensile wires (MS or SS) and can be finished with welded or selvage edges for extra stability. Surface treatments such as galvanizing provide corrosion resistance, while lengths, widths, and hole shapes are tailored as per client specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Crimped Wire Mesh' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |