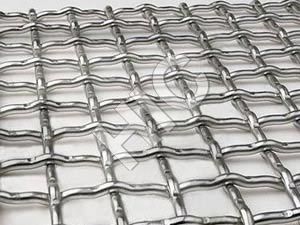

Crimp Netting

Product Details:

- Length Up to 30 meter roll

- Surface Treatment Galvanized, PVC Coated

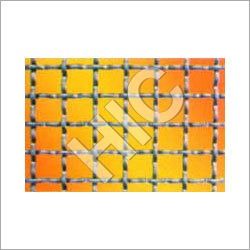

- Hole Shape Square

- Aperture 15 mm to 100 mm

- Wire Gauge 2 mm to 6 mm

- Product Type Crimped Wire Netting

- Mesh Type Woven Mesh

- Click to View more

Crimp Netting Price And Quantity

- 1 Sheet

Crimp Netting Product Specifications

- 15 mm to 100 mm

- Fencing, Sieving, Industrial Screens, Security Barriers

- Low carbon steel, Stainless steel

- Galvanized, PVC Coated

- Mild Steel, Stainless Steel

- Up to 30 meter roll

- Square

- Custom sizes available

- Silver, Green

- Crimped

- 2 mm to 6 mm

- Depends on mesh size and material

- 2 mm to 6 mm

- Woven Mesh

- Crimped Wire Netting

Crimp Netting Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- 5 Sheet Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

Crimp Netting

Since inception in the year 1969, we have establish ourselves as a leading manufacturers, exporters and suppliers of optimum quality Crimp Netting. This wire mesh is precisely manufactured under the direction of our ingenious professionals by making use of superior quality brass, stainless steel, carbon steel and many more. The offered wire mesh has the stable structure and is perfect to be used in coal and mine, building etc. fields. Our provided Crimp Netting is available in various specifications as per the requirement laid down by our clients.

Features:

-

Withstand all extreme weather conditions

-

Durable finish standard

-

Strong in structure

-

Less maintenance

Superior Strength and Longevity

Engineered with high-tensile wire and robust construction, Crimp Netting offers a service life of 5 to 15 years depending on material selection and operating conditions. Perfect for demanding industrial and agricultural environments, it withstands significant stress, ensuring long-term reliability.

Versatile Applications and Customization

Crimp Netting is suitable for various uses including fencing, industrial screening, sieving, and providing security barriers. With custom options for hole shapes, aperture sizes, mesh types, and finishes like galvanization or PVC coating, it accommodates unique project requirements effectively.

FAQs of Crimp Netting:

Q: How is Crimp Netting installed in agriculture and industrial environments?

A: Crimp Netting can be mounted on frames, posts, or existing structures. Installation methods depend on the application areafencing typically requires posts and fasteners, while sieving or industrial screens involve securing the mesh within designated frames using clamps or fixings.Q: What makes the tensile strength of Crimp Netting suitable for harsh environments?

A: The netting uses high-tensile wires of 2 mm to 6 mm diameter, manufactured from low carbon or stainless steel alloy, providing outstanding durability and resistance to mechanical stress, making it ideal for construction, mining, and industrial processes.Q: When should I choose a galvanized or PVC-coated surface treatment for my netting?

A: Surface treatments are chosen based on exposure. Galvanized netting is recommended for corrosion-prone areas, while PVC-coated mesh offers additional protection and aesthetic options, particularly in environments requiring enhanced weather or chemical resistance.Q: Where can I use Crimp Netting with high temperature resistance?

A: Stainless steel Crimp Netting can be used in environments with temperatures up to 400C, making it suitable for applications like industrial screening in kilns, ovens, or high-temperature processing lines.Q: What is the process for customizing the dimensions and aperture sizes of Crimp Netting?

A: Customization involves specifying the required roll width (up to 2 meters), length (up to 30 meters), wire gauge, aperture size (15 mm to 100 mm), and edge type. Manufacturers adjust the mesh style and finishing to meet project specifications.Q: How does using Crimp Netting benefit my operations in the mining and food processing industries?

A: Crimp Netting enhances safety, efficiency, and operational reliability by providing robust barriers, effective sieves, and secure screening optionsensuring optimal material separation and workforce protection in mining and food processing facilities.Q: What type of edge is recommended for security barriers, and why?

A: Selvage edges are preferred for security barriers because they improve structural integrity and reduce the risk of unraveling, ensuring enhanced durability and resistance to tampering or accidental damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Crimped Wire Mesh' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |