SS Wire Mesh

Product Details:

- Aperture 0.5 mm to 50 mm

- Wire Gauge 10 to 24 SWG

- Surface Treatment Galvanized / Plain / PVC Coated

- Hole Shape Square

- Length 30 meter (Standard roll length)

- Product Type Wire Mesh

- Mesh Type Industrial Mesh

- Click to View more

X

SS Wire Mesh Price And Quantity

- 1 Roll

SS Wire Mesh Product Specifications

- Wire Mesh

- Galvanized / Plain / PVC Coated

- SS 304 / SS 316 / SS 316L

- Square

- 30 meter (Standard roll length)

- Varies as per dimensions and wire gauge

- Silver

- Woven / Welded Mesh

- 0.5 mm to 50 mm

- Industrial Mesh

- Filtration, Fencing, Sieving, Construction, Industrial Usage

- 10 to 24 SWG

- Stainless Steel (Grade 304, 316, 316L)

- Custom & Standard: 1 meter, 1.2 meter, 2 meter width

- 0.5 mm to 2.5 mm

SS Wire Mesh Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- 5 Roll Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Middle East, Africa, Asia

- All India

Product Description

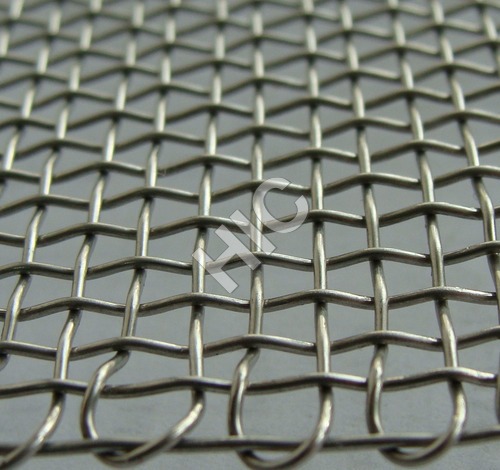

SS Wire Mesh

Based on the latest technological advancements, we are offering a premium quality range of SS Wire Mesh that is used as a protective guard or curtain. The offered mesh is used in different industrial sector such as chemical rubber, fertilizers, sugar mills, petrochemical and many more. This wire mesh is manufactured under the guidance of our skilled professionals by inculcating modern techniques and quality assured raw materials. Furthermore, we provide this SS Wire Mesh in various lengths and thicknesses as per the requirements laid down by our esteemed clients.

Features:

-

Abrasion resistance

-

Rust proof

-

High tensile strength

-

Less maintenance

Superior Material and Construction

Manufactured using SS 304, SS 316, and SS 316L grades, the mesh offers impressive resistance to corrosion, chemicals, and extreme temperatures. Stainless steel ensures long-term reliability in demanding environments, such as industrial filtration, food processing, and fencing.

Customization Options

Available in a range of mesh styles, wire diameters, lengths, and widths, our wire mesh can be tailored to various industrial and construction requirements. Customers can select from different edge finishes, weave patterns, and surface treatments according to their project needs.

Wide Range of Applications

From sieving and filtration to fencing and construction, SS Wire Mesh provides robust solutions across indoor and outdoor settings. Its high tensile strength and chemical resistance make it ideal for heavy-duty usage in industrial, agricultural, and commercial operations.

FAQs of SS Wire Mesh:

Q: How is the SS Wire Mesh typically used in industrial environments?

A: The SS Wire Mesh is deployed for filtration, sieving, fencing, and construction applications. Its high tensile strength and resistance to chemicals and corrosion make it suitable for use in industries such as food processing, chemical manufacturing, mining, and construction.Q: What are the benefits of selecting a specific weave type or edge finish?

A: Choosing between plain, twill, or dutch weaves and cut or selvage edges depends on application requirements. For instance, plain weave offers uniform apertures for general filtration, while dutch weaves provide finer filtration. Selvage edges enhance mesh durability and reduce fraying, especially in high-stress uses.Q: When should I opt for galvanized or PVC-coated SS Wire Mesh over plain finishes?

A: Galvanized or PVC-coated meshes add an extra layer of protection against environmental factors such as moisture and corrosive chemicals. Choose these treatments for outdoor or highly corrosive settings to extend the products lifespan and improve operational safety.Q: Where can customized SS Wire Mesh dimensions be applied most effectively?

A: Custom dimensions are essential for projects with unique size requirements, such as fittings for specific filtration units, architectural panels, or security enclosures. Our mesh is available in widths of 1, 1.2, and 2 meters or tailored as needed, accommodating almost any industrial application.Q: What is the manufacturing process of SS Wire Mesh and how does it ensure quality?

A: SS Wire Mesh is produced using advanced weaving or welding techniques, utilizing high-grade stainless steel wires. Processes are carefully monitored to ensure uniform opening, precise weave structure, and reliable tensile strength, meeting stringent industrial standards.Q: How does the SS Wire Mesh perform under high temperatures and in corrosive environments?

A: The mesh is engineered to withstand temperatures up to 800C and resists acids, alkalis, and oxidation. Its excellent corrosion resistance allows it to function effectively outdoors and in chemically aggressive environments, making it suitable for challenging industrial operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |