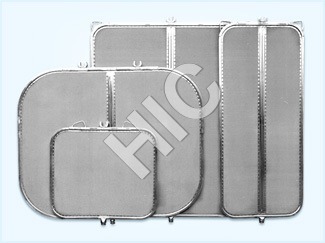

Circle Shape Filters

Product Details:

- Aperture 2 mm

- Wire Gauge 24 SWG

- Surface Treatment Galvanized / Polished

- Hole Shape Circle

- Length Customizable as per requirement

- Product Type Wire Mesh Filter Disc

- Mesh Type Fine Mesh

- Click to View more

X

Circle Shape Filters Product Specifications

- Galvanized / Polished

- SS304, SS316, MS

- 0.56 mm

- Customizable as per requirement

- Circle

- Stainless Steel / Mild Steel

- Woven

- 50 mm Diameter (Standard)

- 2 mm

- Fine Mesh

- Wire Mesh Filter Disc

- 6 grams (approx. per piece)

- 24 SWG

- Filtration, Sieving, Industrial, Chemical, and Food Processing

- Silver

Product Description

Circle Shape Filters

Based on the latest technological advancements, we are offering a premium quality range of Circle Shape Filters. The offered is used in different industrial sector such as chemical rubber, fertilizers, sugar mills, petrochemical and many more. This Filters is manufactured under the guidance of our skilled professionals by inculcating modern techniques and quality assured raw materials. Furthermore, we provide this Circle Shape Filters in various lengths and thicknesses as per the requirements laid down by our esteemed clients.

Features:

-

Abrasion resistance

-

Rust proof

-

High tensile strength

-

Less maintenance

Precision and Durability

Crafted with precision-punched perforations and smooth laser-cut edges, these circle shape filters provide reliable, long-term performance. Their robust fabrication allows for operation in demanding environments, ensuring both safety and efficiency.

Versatile Applications

Suitable for filtration, sieving, and processing across industrial, chemical, and food sectors, these filters are designed to work effectively with water, air, gas, and oils. They are adaptable for use in a wide range of systems, from large-scale plants to specialized machinery.

Customization and Compliance

We offer size, mesh, and material customization options to meet specific project requirements. Adhering to international ASTM and DIN standards, our filters deliver consistent quality and compatibility for global applications. Minimum order quantities start at just 100 pieces.

FAQs of Circle Shape Filters:

Q: How are Circle Shape Filters typically used in industrial settings?

A: These filters are designed for use in a wide variety of industrial processes, including the filtration of water, air, gas, and oil. They are also ideal for sieving and contaminant separation in chemical and food processing industries, ensuring product purity and system efficiency.Q: What benefits do the smooth laser-cut edge and precision-punched perforations provide?

A: The smooth laser-cut edge ensures a secure, seamless fit in filtration assemblies, reducing the risk of leaks or material snagging. Precision-punched perforations deliver consistent filtration, maximizing durability and optimizing flow rates for enhanced operational reliability.Q: When should I consider customizing my Circle Shape Filters?

A: Customization is recommended if your application requires specific dimensions, mesh styles, or materials not covered by standard offerings. Custom filters help achieve precise filtration needs, adapting to unique system configurations or challenging operating conditions.Q: What is the process for ordering customized Circle Shape Filters?

A: Simply specify your required dimensions, preferred material (such as SS304, SS316, or mild steel), mesh type, and aperture size. Our team will assist with technical recommendations and provide options, ensuring your filters closely match your operational requirements. Minimum order is 100 pieces.Q: Where do these filters originate and are they internationally compliant?

A: All our Circle Shape Filters are produced in India, adhering to ASTM and DIN standards. This ensures international compatibility and high-quality performance whether you are a manufacturer, distributor, or end user.Q: How does the surface treatment enhance filter longevity and performance?

A: Each filter is either galvanized or polished, significantly increasing its resistance to corrosion and wear. This treatment ensures long-term usability, particularly in harsh or corrosive environments.Q: What is the main advantage of choosing a high corrosion-resistant filter for my application?

A: High corrosion resistance protects your equipment from breakdowns caused by rust or chemical reaction, extending the lifespan of both the filter and the machinery it protects, ultimately reducing maintenance costs and unplanned downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sieves' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |