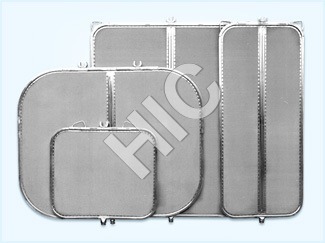

Pressure Leaf Filters

Product Details:

- Length As per design specification or requirement

- Surface Treatment Polished / Passivated

- Wire Gauge Available in various gauges as per design

- Aperture 0.5 mm to 2 mm (customizable)

- Hole Shape Slotted / Rectangular

- Product Type Pressure Leaf Filter

- Mesh Type Leaf / Sieve Mesh

- Click to View more

X

Pressure Leaf Filters Price And Quantity

- 1 Piece

Pressure Leaf Filters Product Specifications

- Silver metallic

- SS304 / SS316 / SS316L

- Welded Mesh

- Slotted / Rectangular

- 0.5 mm to 2 mm (customizable)

- Stainless Steel (SS304, SS316, SS316L) or as specified

- 0.5 mm to 2 mm

- Available in various gauges as per design

- Leaf / Sieve Mesh

- Depends on leaf size and material

- Standard & Custom Sizes

- Polished / Passivated

- Pressure Leaf Filter

- As per design specification or requirement

Pressure Leaf Filters Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1000 Piece Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

With an assistance of industrial expertise in this domain, we have enabled ourselves to manufacture, export and supply the finest quality Pressure Leaf Filters. At our advanced production unit, the offered filters are manufactured using optimum grade raw materials and pioneering techniques as per set industry standard. To pass out fluids with high pressure, these filters are used in water treatment plant. In addition, the provided Pressure Leaf Filters can be availed by our valuable patrons at cost effective rates.

Features:

- Sturdy design

- Rust proof surface

- High strength

- Flawless finish

Precise and Versatile Filtration Solutions

Pressure leaf filters are designed to deliver reliable, fine filtration while accommodating demanding industrial conditions. The system supports a wide range of filter sizes, materials, and operating parameters, letting users tailor each unit for specific application requirements. These filters ensure high flow rates, robust construction, and adaptable cleaning mechanisms to maintain operational efficiency.

Custom Engineering for Varied Applications

From stainless steel to mild steel vessels, and silicon to Viton gaskets, every pressure leaf filter can be constructed to match user specifications. The systems compatibility with diverse end connections and mounting types guarantees seamless integration into existing process lines, making it an excellent solution for distributors, manufacturers, and exporters seeking adaptable filtration equipment.

FAQs of Pressure Leaf Filters:

Q: How does a pressure leaf filter operate in industrial filtration processes?

A: Pressure leaf filters utilize a series of vertical or horizontal filter leaves enclosed within a pressure vessel. Liquid passes through the leaves, where contaminants are trapped, allowing clean filtrate to exit. The process can be manually or automatically cleaned by vibrating the leaves to remove accumulated solids.Q: What are the typical applications for pressure leaf filters?

A: These filters are commonly used in edible oil refining, chemical manufacturing, pharmaceutical processing, and other industries requiring efficient liquid-solid separation. Their customizable features make them suitable for a broad spectrum of filtration needs.Q: When should I choose automatic vibration cleaning over manual cleaning for my filter?

A: Automatic vibration cleaning is recommended for processes involving frequent operation or high solid loads, as it enhances cleaning efficiency and reduces downtime. Manual cleaning may suffice for intermittent applications or smaller-scale systems.Q: Where can pressure leaf filters be installed in a processing plant?

A: Depending on your facility layout, these filters can be mounted on a skid for mobility or installed directly to the floor for stability. The mounting type can be specified based on space availability and operational requirements.Q: What benefits do different sealing gaskets offer in pressure leaf filters?

A: Silicon, EPDM, and Viton gaskets each provide distinct advantages depending on process conditions. Silicon is suitable for high-temperature applications, EPDM works well with certain chemicals, and Viton is highly resistant to aggressive solvents, ensuring optimal sealing and durability.Q: How is the filtration rating determined for pressure leaf filters?

A: Filtration rating is defined by the mesh size and wire gauge of the filter leaf, ranging from 5 to 100 microns. The choice depends on the level of clarity and contaminant removal required for your specific process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sieves' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |