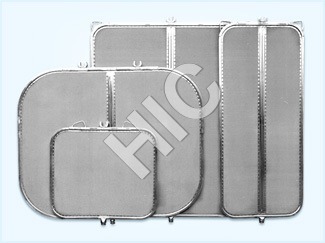

Sparkler Filter Screen

Product Details:

- Hole Shape Round

- Length 300 mm

- Wire Gauge 22 SWG

- Surface Treatment Polished

- Aperture 0.4 mm

- Product Type Filter Screen

- Mesh Type Woven Mesh

- Click to View more

X

Sparkler Filter Screen Price And Quantity

- 1 Piece

Sparkler Filter Screen Product Specifications

- Silver

- Polished

- 300 mm diameter

- 22 SWG

- Plain Weave

- Round

- Woven Mesh

- SS 304/316

- 300 mm

- Approx. 120 g

- 0.7 mm

- Filter Screen

- Stainless Steel (SS 304/316)

- Liquid Filtration, Pharma, Chemical, and Food Processing

- 0.4 mm

Sparkler Filter Screen Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

To gain the utmost recognition on this industry, we are affianced in manufacturing, exporting and supplying an excellent array of Sparkler Filter Screen. Our adroit engineers use supreme quality raw materials and cutting edge techniques to design and manufacture the provided screen. Having tiny size hole and high strength, the offered screen is used for filtering purpose. In addition, this Sparkler Filter Screen can be availed by our customers at pocket friendly rates.

Features:

- Excellent finish

- Easy to use

- Provide fine and dust free powder

- Rust proof surface

Superior Filtration Performance

Achieve fine filtration down to 5 microns with the Sparkler Filter Screens expertly woven mesh. The circular shape and ring-finished edges ensure tight, reliable sealing for consistent performance in sparkler filter assemblies, making it a trusted solution for critical liquid filtration processes.

Exceptional Corrosion Resistance

Manufactured from stainless steel SS 304/316, this screen offers outstanding resilience against chemical attack, providing longevity and robust performance even in challenging environments. It remains reliable under operating temperatures of up to 250C, supporting demanding industrial applications.

Convenient Reusability & Maintenance

The Sparkler Filter Screen is reusable, making it a cost-effective and environmentally friendly choice. Its polished surface simplifies cleaning and maintenance, allowing quick turnaround during process cycles in pharmaceutical, food, and chemical industries.

FAQs of Sparkler Filter Screen:

Q: How is the Sparkler Filter Screen installed in standard filter assemblies?

A: The screens circular shape and ring-finished edges allow for easy and secure fitting into standard sparkler filter assemblies. It is simply placed in the designated slot, ensuring a tight seal and optimal filtration performance without the need for specialized tools.Q: What is the benefit of using stainless steel (SS 304/316) for the filter screen?

A: Stainless steel SS 304/316 offers excellent resistance to corrosion, high durability, and compatibility with a wide range of chemicals. This makes the filter screen suitable for harsh environments in pharmaceutical, chemical, and food processing applications, ensuring a longer service life.Q: When should I replace or clean the Sparkler Filter Screen?

A: Regular cleaning is recommended after each filtration cycle, especially if high particulate load is encountered. Replacement should be considered if there is visible damage, deformation, or reduced filtration efficiency. Its reusability helps lower operational costs over time.Q: Where can the Sparkler Filter Screen be used?

A: This filter screen is widely used in liquid filtration processes across pharmaceutical, chemical, and food processing industries in India and abroad. Its compatibility with standard sparkler filter assemblies makes it suitable for diverse industrial environments.Q: What is the process for cleaning and maintaining the filter screen?

A: After use, remove the screen from the assembly and rinse it with appropriate cleaning solutions compatible with stainless steel. The polished surface and woven mesh design facilitate residue removal, enabling rapid maintenance and repeated reuse.Q: How does the micron rating improve filtration outcomes?

A: The screens ability to filter particles down to 5 microns ensures high purity levels in processed liquids, protecting downstream equipment and ensuring product quality in sensitive applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sieves' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |