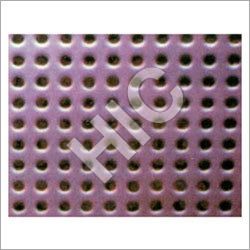

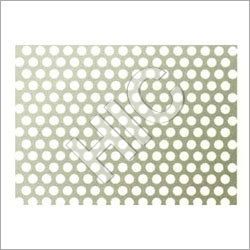

Perforated Metal Sheets

Product Details:

- Process Perforation, Shearing, Cutting

- Temper Hard, Soft

- Surface Treatment Galvanized, Powder Coated, Mill Finish

- Shape Round, Square, Slot, Custom

- Standard ASTM, ISO

- Material Stainless Steel, Mild Steel, Aluminum

- Type Perforated Metal Sheet

- Click to View more

X

Perforated Metal Sheets Product Specifications

- Perforated Metal Sheet

- Round, Square, Slot, Custom

- High strength, corrosion resistance, uniform perforation, precise dimensions

- 0.5 mm to 5 mm

- Filtration, screening, ventilation, architecture, machinery protection, decorative panels

- ASTM, ISO

- Cold Rolled, Hot Rolled, Punching

- Galvanized, Powder Coated, Mill Finish

- Hard, Soft

- Stainless Steel, Mild Steel, Aluminum

- Perforation, Shearing, Cutting

Product Description

We have been earned an immense reputation by manufacturing, exporting and supplying top grade array of Perforated Metal Sheets. These sheets are manufactured using quality examined raw materials and innovative techniques at our premises. The offered sheets are ideal to be used for cladding, fencing and ceiling purpose. Along with this, the provided Perforated Metal Sheets are easily available in the market at cost effective rates.

Features:

Features:

- High strength

- Resist corrosion

- Heat resistance

- Easy to use

Versatile Hole Patterns & Sizes

Choose from round, square, slotted, hexagonal, or fully custom perforation designs to suit your specific requirements. The sheets support hole diameters from 0.5 mm to 50 mm and open area percentages ranging from 2% to 60% for optimal airflow or filtration. Customization ensures perfect fit and function for your application.

Durability & Surface Treatments

Manufactured using cold or hot rolled techniques, these sheets achieve high strength and exceptional flatness. Surface treatments like galvanizing or powder coating enhance corrosion resistance and appearance, making them suitable for harsh environments. Clean-cut, burr-free edges or custom edging deliver professional finishing for every installation.

Tailored for Multiple Applications

These perforated metal sheets are widely used in industries for filtration, machinery guarding, air diffusers, facades, and even decorative purposes. With ready stock in standard sizes and the flexibility to customize large orders, they are ideal for distributors, exporters, builders, and manufacturers across India.

FAQs of Perforated Metal Sheets:

Q: How are perforated metal sheets manufactured?

A: Perforated metal sheets are produced using cold or hot rolled processes, followed by punching, shearing, or cutting to achieve precise hole patterns such as round, square, slotted, hexagonal, or custom designs. Each sheet is finished to ensure clean, burr-free edges.Q: What options are available for customizing perforated metal sheets?

A: You can customize hole patterns, diameters (ranging from 0.5 mm to 50 mm), sheet size (up to 1220 mm x 2440 mm or tailored dimensions), thickness (0.5 mm to 5 mm), material type, surface treatment (galvanized, powder coated, mill finish), color, and edge finishing to match your requirements.Q: When should I choose perforated metal sheets for my project?

A: Perforated metal sheets are ideal when you need high strength, uniform perforation, and corrosion resistance. They are suitable for projects involving filtration, ventilation, screening, architectural features, or machinery protection in both indoor and outdoor settings.Q: Where can perforated metal sheets be used?

A: These sheets are commonly used in industrial, architectural, and commercial settings, including building facades, filtration units, screens, machinery guards, air distribution systems, and decorative applications, thanks to their robust build and design flexibility.Q: What is the process for ordering custom-sized sheets or bulk orders?

A: For custom dimensions or bulk requirements, you can submit your specifications such as material, pattern, thickness, hole diameter, and required quantity. The manufacturer or distributor will confirm feasibility, lead times, and provide a quotation, followed by manufacturing to order.Q: How do I benefit from using perforated metal sheets in harsh environments?

A: With high corrosion resistance (thanks to options like stainless steel or galvanizing), robust tensile strength, and specialized surface treatments, these sheets maintain structural integrity and appearance even in demanding indoor or outdoor environments.Q: What kinds of edge finishes are available?

A: You can opt for standard clean-cut edges, burr-free finishing, or request custom edging to seamlessly match the installation requirements of your project.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Sheets' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |