Industrial Perforated Sheets

Product Details:

- Process Punching, Pressing

- Temper Hard, Soft, Half Hard

- Surface Treatment Polished, Galvanized, Powder Coated

- Standard ASTM, IS, JIS

- Material Stainless Steel, Mild Steel, Galvanized Iron, Aluminum

- Type Perforated Sheet

- Technique Cold Rolled, Hot Rolled, Punching

- Click to View more

Industrial Perforated Sheets Price And Quantity

- 1 Sheet

Industrial Perforated Sheets Product Specifications

- 0.5 mm to 10 mm

- Stainless Steel, Mild Steel, Galvanized Iron, Aluminum

- Polished, Galvanized, Powder Coated

- ASTM, IS, JIS

- Industrial Filtration, Sieving, Guarding Machinery, Ventilation, Architecture

- Corrosion Resistant, Durable, Fine Finish

- Perforated Sheet

- Punching, Pressing

- Hard, Soft, Half Hard

- Cold Rolled, Hot Rolled, Punching

Industrial Perforated Sheets Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1000 Sheet Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

By following latest industry norms, we are engaged in manufacturing, exporting and supplying excellent quality Industrial Perforated Sheets. Our offered sheets are manufactured with indigenous methodology and using quality assured raw materials at our sophisticated manufacturing unit. The provided sheets are used in chemical, construction, steel and many more industries for general purposes. These Industrial Perforated Sheets are available in varied sizes, thicknesses and can be availed at industry leading prices.

Features:

-

Rust resistance

-

High strength

-

Immaculate finish

-

Rugged construction

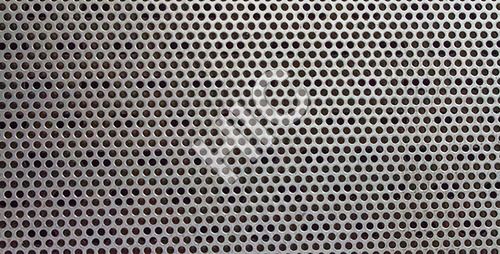

Sheet Thickness from 0.30 mm upto 10 mm / Hole dia from 0.5mm upto 80mm maximum width upto 1800 mm Material MFR : In MS, Brass, Copper, Zinc Stainless Steel, Aluminium and etc. Special type perforation can also be undertaken according to as per customers demand and application

Superior Quality with Versatile Applications

Our industrial perforated sheets cater to a wide spectrum of uses, from effective filtration and sieving in manufacturing plants to enhancing both safety and ventilation in machinery, as well as creative implementation in architectural designs. Engineered for reliability, these sheets combine strength, durability, and an attractive finish to perform in harsh industrial environments.

Premium Materials and Advanced Processes

Using high-grade materials like stainless steel, mild steel, galvanized iron, and aluminum, our perforated sheets are manufactured utilizing cold and hot rolling, punching, and pressing techniques. Surface treatments such as polishing and powder coating bolster corrosion resistance and extend the lifespan of each sheet, ensuring dependable performance.

FAQs of Industrial Perforated Sheets:

Q: What materials are available for your industrial perforated sheets?

A: Our industrial perforated sheets are available in a selection of materials including stainless steel, mild steel, galvanized iron, and aluminum, catering to various usage conditions and requirements.Q: How is the corrosion resistance of these perforated sheets ensured?

A: Corrosion resistance is achieved through the choice of high-quality metals, like stainless steel and galvanized iron, and enhanced further with surface treatments such as polishing, galvanization, and powder coating.Q: When should I select a specific thickness for industrial applications?

A: The ideal sheet thickness depends on your applicationthinner gauges (starting from 0.5 mm) are suited for filtration and ventilation, while thicker sheets (up to 10 mm) provide extra durability for guarding machinery and structural uses.Q: Where can these perforated sheets be installed?

A: You can install our sheets in numerous environments, including industrial plants for filtration and sieving, machinery areas for guards and protection, ventilations systems, and as decorative or functional elements in building architecture.Q: How are your perforated sheets manufactured?

A: Our sheets are produced using advanced cold rolled, hot rolled, punching, and pressing techniques. These processes follow international standards such as ASTM, IS, and JIS for uniform quality and precision.Q: What are the benefits of using perforated sheets in architecture and filtration?

A: In architecture, they provide aesthetic appeal, improved ventilation, and structural support. For filtration, their precisely punched patterns ensure efficient separation of particles while maintaining strength and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Perforated Sheets' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |