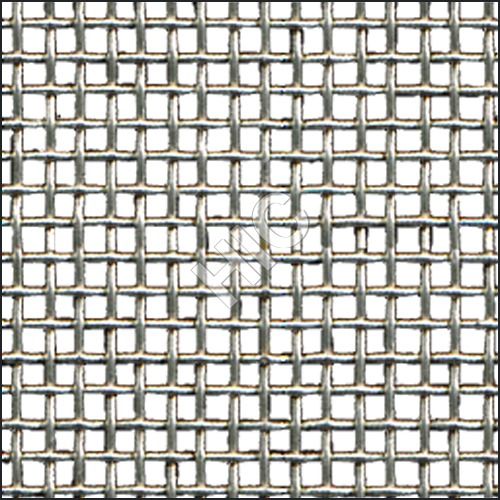

Brass Wire Mesh

Product Details:

- Surface Treatment Polished

- Wire Gauge 10 to 60 SWG

- Length 30 meters (standard roll), customizable

- Hole Shape Square

- Aperture 0.2 mm to 2 mm

- Product Type Woven Brass Wire Mesh

- Mesh Type Woven Mesh

- Click to View more

Brass Wire Mesh Price And Quantity

- 1 Roll

Brass Wire Mesh Product Specifications

- 10 to 60 SWG

- Polished

- Variable (depends on mesh size and roll dimensions)

- 30 meters (standard roll), customizable

- 0.16 mm to 1.63 mm

- Woven Brass Wire Mesh

- Width: 1 meter, Length: 30 meters

- Filtration, Sieving, Decoration, EMI Shielding

- Brass (Copper-Zinc Alloy)

- CuZn (65% Copper, 35% Zinc)

- Woven Mesh

- Plain Weave

- 0.2 mm to 2 mm

- Square

- Golden

Brass Wire Mesh Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- 5 Roll Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

Brass Wire Mesh

Based on the latest technological advancements, we are offering a premium quality range of Brass Wire Mesh that is used as a protective guard or curtain. The offered mesh is used in different industrial sector such as chemical rubber, fertilizers, sugar mills, petrochemical and many more. This wire mesh is manufactured under the guidance of our skilled professionals by inculcating modern techniques and quality assured raw materials. Furthermore, we provide this Brass Wire Mesh in various lengths and thicknesses as per the requirements laid down by our esteemed clients.

Features:

-

Abrasion resistance

-

Rust proof

-

High tensile strength

-

Less maintenance

Excellent Corrosion and Temperature Resistance

Brass wire mesh demonstrates robust corrosion resistance, especially in environments free from acidic exposure. Suitable for continuous use up to 200C, it maintains its integrity under elevated temperatures, making it ideal for industrial filtration and screening. Its high melting point of approximately 900C further enhances operational safety and longevity in demanding settings.

Versatile Weave Options for Custom Applications

Primarily manufactured in plain weave for standard applications, brass wire mesh also offers twill weave options for specialized tasks. With opening sizes from 0.2 mm to 2 mm and selectable edge finishes such as cut edge or selvage edge, customization ensures precise fit for filtration, sieving, or decorative implementations. Custom roll dimensions are available to suit project needs.

FAQs of Brass Wire Mesh:

Q: How is brass wire mesh manufactured, and what weave types are available?

A: Brass wire mesh is produced by weaving copper-zinc alloy wires in either a plain weavemost common for uniformity and strengthor a twill weave, preferred for specific applications requiring flexibility or a different visual pattern. Both types are crafted to deliver reliable filtration and separation.Q: What environments are suitable for using brass wire mesh?

A: This mesh excels in non-acidic environments due to its strong resistance to corrosion. It is therefore frequently used in industries such as petroleum, chemical processing, food production, and mining, where exposure to harsh but non-acidic conditions is expected.Q: When is a cut edge or selvage edge recommended for brass wire mesh rolls?

A: A cut edge is suitable for standard installations and routine use, while a selvage edge is recommended when extra durability or enhanced resistance to fraying along the border is necessary, such as in high-throughput or specialty filtration setups.Q: Where can brass wire mesh be applied besides industrial filtration?

A: Apart from filtration and sieving, brass wire mesh is employed for decorative applications due to its attractive golden finish, and for EMI shielding owing to its superior electrical conductivity. Its also used as reinforcement in construction and architectural projects.Q: What are the benefits of brass wire mesh for filtration and sieving processes?

A: Brass wire mesh provides uniform openings, high strength, and excellent dimensional stability. Its polished surface and high conductivity make cleaning and maintenance easy, and its resistance to heat and corrosion ensures long-term reliability in demanding sieving and separation tasks.Q: How is brass wire mesh packed and shipped to ensure quality?

A: Rolls of brass wire mesh are wrapped in moisture-proof paper or plastic, safeguarding them against environmental damage during transit and storage. Custom packaging solutions are available from distributors, manufacturers, and suppliers in India for bulk orders or specialized needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Wire Mesh' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |