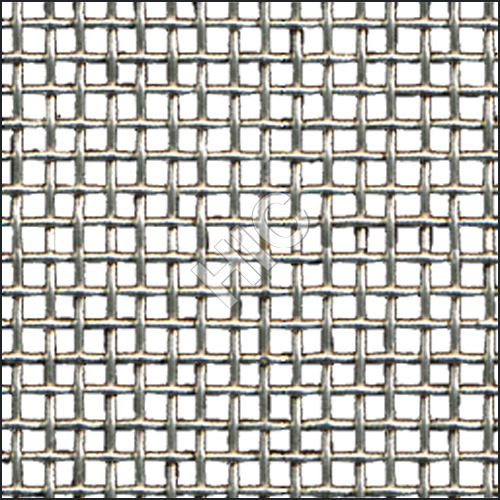

Woven Wire Cloth

Product Details:

- Surface Treatment Galvanized / Plain / PVC Coated / Stainless Steel

- Wire Gauge Up to 16 SWG

- Aperture Varies as per mesh size (typically 0.025 mm to 10 mm)

- Length 15-30 meters (standard roll length)

- Hole Shape Square

- Product Type Woven Wire Cloth

- Mesh Type Fine, Medium, Coarse

- Click to View more

X

Woven Wire Cloth Price And Quantity

- 1 Sheet

Woven Wire Cloth Product Specifications

- Width: 1 m to 2 m (custom available)

- Up to 16 SWG

- Filtration, Sieving, Fencing, Industrial, Agriculture, Construction

- SS304, SS316, GI, Mild Steel

- Varies as per mesh size (typically 0.025 mm to 10 mm)

- Square

- 15-30 meters (standard roll length)

- Woven

- Stainless Steel / Mild Steel / Galvanized Iron

- Woven Wire Cloth

- Silver / Metallic Grey

- Galvanized / Plain / PVC Coated / Stainless Steel

- 0.025 mm to 2 mm

- As per specification (varies by mesh & material)

- Fine, Medium, Coarse

Woven Wire Cloth Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 5 Sheet Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Africa, Middle East, Asia

- All India

Product Description

To catch up the colossal recognition in this domain, we are betrothed in manufacturing, exporting and supplying a supreme grade array of Woven Wire Cloth. Provided cloth is designed and manufactured at our premises using top notch quality raw materials and cutting edge techniques as per set industry norms. For its better-quality filtration factor, this cloth is highly demanded among the customers. Moreover, the offered Woven Wire Cloth is available in different sizes for our customers at reasonable rates.

Features:

- Strongly design

- Extended durability

- Rust proof surface

- Fine finish

Versatile Applications, Robust Performance

Designed for demanding environments, this woven wire cloth is used across industries such as filtration, sieving, agriculture, construction, and fencing. The selection of edge types and weaves ensures optimal fit and performance for varied projects, while high-grade materials guarantee long-lasting reliability.

Customizable to Your Specifications

Responding to diverse industrial needs, our wire mesh is highly customizable in dimensions, mesh type, aperture, and wire gauge. Available in different materials and finishes, each order can be tailored for specific applications, ensuring you receive a product that perfectly matches your requirements.

Reliable Quality, Secure Packaging

Our woven wire cloth is meticulously manufactured and inspected for quality. After production, each roll is securely packed in plastic/woven bags or robust wooden cases to ensure it reaches you in ideal condition, ready for immediate deployment or long-term storage.

FAQs of Woven Wire Cloth:

Q: How is the woven wire cloth manufactured and what wire gauges are available?

A: The woven wire cloth is produced using advanced weaving techniques, available in plain, twill, and Dutch weaves. Wire gauges up to 16 SWG are offered, allowing for precise selection to suit different filtration and structural needs.Q: What types of edge finishes can I choose from for my application?

A: We provide various edge types including cut edge, folded edge, and selvedge. This flexibility enables you to select the edge finish that best suits your installation requirements and longevity expectations.Q: When should I opt for stainless steel over galvanized or mild steel?

A: Stainless steel is recommended when high temperature resistance (up to 800C) or excellent corrosion resistance is required, such as in industrial filtration or harsh environments. Galvanized options are suitable for outdoor or moisture-prone applications, while mild steel is ideal for less demanding environments.Q: Where can woven wire cloth be effectively used?

A: Woven wire cloth finds application in industrial filtration, sieving, agricultural screening, fencing, and construction. Its adaptable design and material options ensure effective performance in each of these environments.Q: What is the process for customizing woven wire cloth to specific requirements?

A: Customization is available for dimensions, mesh style, aperture size, wire diameter, and material. Simply provide the specifications you need, and we will manufacture the mesh accordingly to ensure an ideal fit for your project.Q: How is the wire mesh packed for safe transport and storage?

A: Standard rolls (1530 meters in length) are carefully packed in plastic or woven bags, or placed within wooden cases for added protection during transit and storage, ensuring the mesh arrives in optimal condition.Q: What are the main benefits of using your woven wire cloth products?

A: Clients benefit from premium-quality materials ensuring high durability, excellent temperature and corrosion resistance, versatile applications, and a strong emphasis on customization to meet specific operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire Mesh' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |