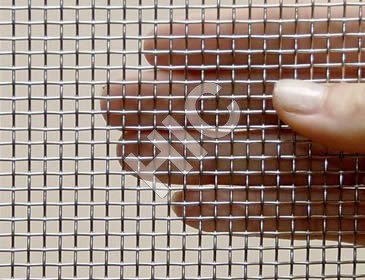

Dutch Woven Plain Weave

Product Details:

- Aperture 0.024 mm to 2 mm

- Wire Gauge 10-50 SWG

- Length 15-30 m (standard roll), customizable

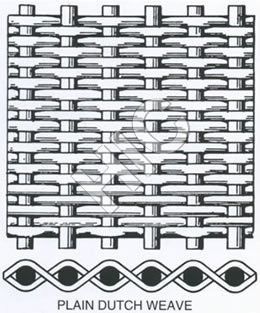

- Hole Shape Rectangular

- Surface Treatment Plain, Galvanized, or Stainless steel finish

- Product Type Dutch Woven Plain Weave Wire Mesh

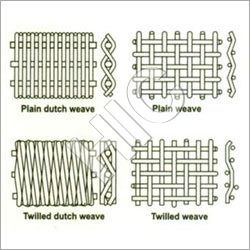

- Mesh Type Dutch Plain Weave

- Click to View more

X

Dutch Woven Plain Weave Price And Quantity

- 1 Roll

Dutch Woven Plain Weave Product Specifications

- Dutch Woven Plain Weave Wire Mesh

- Width: 0.5 m to 2 m, Length as per requirement

- Available in SS304, SS316 and other special alloys

- 0.024 mm to 2 mm

- 0.025 mm - 1.6 mm

- Woven Wire Mesh

- Dutch Plain Weave

- Stainless Steel (SS304, SS316), Brass, Copper

- Rectangular

- 10-50 SWG

- 15-30 m (standard roll), customizable

- Silver/Metallic

- Filtration, Sieving, Air and Liquid Filtration, Oil & Gas, Chemical processing

- Plain, Galvanized, or Stainless steel finish

- As per mesh size and dimensions

Dutch Woven Plain Weave Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 5 Roll Tones Per Month

- 1 Week

- Yes

- Within a certain price range free samples are available

- Customize Packaging

- Middle East, Africa, Asia

- All India

Product Description

We hold an immense clientele in the market by manufacturing, exporting and supplying a wide array of Dutch Woven Plain Weave. This product is widely used at construction site to separate the dust particles from sands. With the use of stainless steel and brass, provided product is manufactured at our premises under the guidance of deft professionals. Furthermore, the offered Dutch Woven Plain Weave can be availed by our precious patrons at rock bottom rates.

Key Points:

Key Points:

- Provide ultra fine filtration

- Highly durable

- Sturdy design

- Easy to use

Versatile High-Density Filtration Mesh

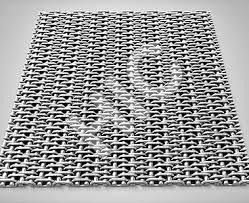

Plain Dutch Weave wire mesh stands out for its extra-dense weaving pattern that enables precision filtration. Its rectangular hole shape and robust wire gauge options make it suitable for sieving and separating fine particulates. This mesh supports a filtration rating down to 5 microns, ideal for demanding industrial processes requiring stringent particle retention.

Excellent Temperature and Corrosion Resistance

Constructed from stainless steel (grades SS304 and SS316), brass, or copper, the mesh exhibits excellent resistance to corrosion and can withstand temperatures up to 600C, depending on the chosen material. This durability makes it highly reliable for chemical processing, oil & gas, and air or liquid filtration operations in harsh environments.

FAQs of Dutch Woven Plain Weave:

Q: How is Dutch Woven Plain Weave wire mesh used in industrial filtration?

A: Dutch Woven Plain Weave wire mesh is employed to filter and separate fine particles from liquids and gases. Its dense structure allows for precise filtration, making it suitable for chemical processing, oil & gas, and air or liquid filtration in industrial applications.Q: What customization options are available for mesh dimensions and finishes?

A: Customization includes roll lengths from 15 to 30 meters, widths between 0.5 m and 2 m, and cut-to-size sheets. You can also choose between plain, galvanized, or stainless steel surface treatments, as well as select different edge types like plain, welded, or bounded edges.Q: When should I select stainless steel over brass or copper for Dutch Weave mesh?

A: Stainless steel is preferred for applications requiring high corrosion resistance and temperature durability, such as chemical processing or high-temperature filtration. Brass and copper are selected for specific environments where their properties best suit the filtration requirements.Q: Where can Dutch Woven Plain Weave mesh be sourced in India?

A: This mesh is distributed, exported, manufactured, supplied, and wholesaled by various companies in India specializing in industrial filtration solutions, catering to both domestic and international markets.Q: What is the typical process for ordering customized mesh for filtration?

A: You need to specify filtration rating, dimensions, material type (such as SS304 or SS316), wire diameter, aperture size, surface finish, mesh style, and edge type. Suppliers can then manufacture rolls or sheets tailored to your application requirements.Q: What are the benefits of choosing Plain Dutch Weave over other mesh types?

A: Plain Dutch Weave offers superior particle capture due to its extra-dense weave, high tensile strength, and customizable features, making it especially effective for fine filtration and long-term durability in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Dutch Twilled Weave' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |