Clamps for Stretching Vibrating Screen Cloth

Product Details:

- Length Customizable / As per screen size

- Wire Gauge According to requirement

- Hole Shape Rectangular / Square

- Aperture As per screen mesh

- Surface Treatment Galvanized / Powder Coated / Polished

- Product Type Vibrating Screen Cloth Clamp

- Mesh Type Heavy Duty / Standard

- Click to View more

Clamps for Stretching Vibrating Screen Cloth Product Specifications

- As per screen mesh

- Stainless Steel / Mild Steel

- Varies as per size and design

- Vibrating Screen Cloth Clamp

- As per application requirement

- Galvanized / Powder Coated / Polished

- As per Vibrating Screen specification

- Metallic / Silver / Custom

- Customizable / As per screen size

- According to requirement

- Stretching and securing vibrating screen cloth

- Mild Steel / Stainless Steel (304, 316)

- Heavy Duty / Standard

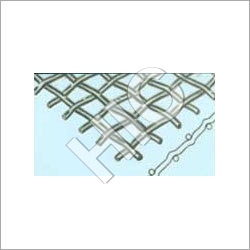

- Woven

- Rectangular / Square

Product Description

With an assistance of our industrial expertise in this domain, we have enabled ourselves to manufacture, export and supply a wide range of Clamps for Stretching Vibrating Screen Cloth. This product is manufactured at our advanced production unit using top notch quality stainless steel and cutting edge techniques. The offered product is used for jointing and fixing vibrating screen cloth on the machine. Moreover, we provide this Clamps for Stretching Vibrating Screen Cloth to our clients at competitive rates.

Features:

- Precisely designed

- Sturdy in construction

- Long lasting life

- Supreme finish

Clamps for Stretching Vibrating Screen Cloth:

| Industrial wire cloth (fine mesh) bolting cloth | S.S any grade Ph. bronze any metal wire | 20 mesh to 500 mesh per liner inch | 0.56 mm (24 Gauge) to 0.025 mm (50 SWG) | Filtering metal powder, chemicals fertilizers, insulators pharmaceuticals screen printing, paints, food and for other industries |

| Heavy mesh/ vibrator screen Square opening Slotted opening | Preferable high carbon steel wire of 0.55 to 0.66% S.S wire of any Grade | 1.6 mm. Sq. opening to 60 mm or as desired | 1.00 mm to mm to 15.00 mm high carbon steel wire having 0.5% carbon For S.S wire: 10.00 mm to 1.6 mm wire dia | Grading & Sizing coal, stone, heavy ore, crushed rock,granite, & other minerals, fertiliser, paper man made fibre industries cement & other industries |

Tailored Solutions for Vibrating Screen Applications

Our clamps offer fully customizable options in terms of length, wire diameter, aperture, and color, ensuring they fit any vibrating screen specification. With choices in material, mesh style, and surface treatment, clients can select the ideal clamp for both standard and heavy-duty applications. Designed to secure and stretch screen cloths effectively, they guarantee optimal screen tension and longevity.

Durable Construction for Demanding Environments

Manufactured using high-grade mild steel or stainless steel (304, 316), these clamps provide robust support in harsh working conditions. The optional galvanized, powder-coated, or polished surface treatments further enhance their performance by preventing rust and wear. Suitable for industrial, mining, and aggregate operations, our clamps deliver long-term reliability even under continuous use.

FAQs of Clamps for Stretching Vibrating Screen Cloth:

Q: How are clamps for vibrating screen cloth installed?

A: Clamps are installed by positioning them along the screen cloths edges and tightening them according to the required tension, ensuring the mesh remains securely stretched during operation. The process may differ depending on the screen size and application requirements.Q: What materials are available for the clamps?

A: Clamps are offered in mild steel and stainless steel (304, 316) to suit varying environmental and operational conditions, providing durability, corrosion resistance, and strength for different screening applications.Q: When should I choose galvanized or powder-coated surface treatments?

A: Galvanized or powder-coated finishes are recommended in highly corrosive environments or where extra durability and extended lifespan are desired, helping to protect the clamps against rust and wear.Q: Where can these clamps be used?

A: These clamps are suitable for use in any facility or application that employs vibrating screen cloth, including mining, aggregate processing, construction, and other heavy-duty industrial settings.Q: What is the benefit of customizable clamp dimensions and apertures?

A: Customizable dimensions and apertures ensure a precise fit with your vibrating screens mesh and frame, optimizing performance, improving screen life, and meeting specific operational requirements.Q: What is the typical process for ordering custom clamps?

A: To order custom clamps, provide specifications like the required length, wire gauge, mesh size, hole shape, surface treatment, and application. We manufacture to your exact requirements to ensure the best possible fit and performance.Q: How do these clamps enhance the usage and performance of vibrating screens?

A: By securely fastening and stretching the screen cloth, these clamps maintain optimal tension, reduce sagging, and prevent displacement, ensuring efficient screening, minimizing downtime, and extending the life of both screens and clamps.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibrating Screen Cloth' category

|

HINDUSTAN INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |